WARNING

YOUR SNOWMOBILE SHOCKS ARE IN NEED OF SERVICING

Change your snowmobile shock oil, and change your life with parts and services from Brad’s A/C Performance & Fink’s Performance Suspension at SnowmobileShocks.com

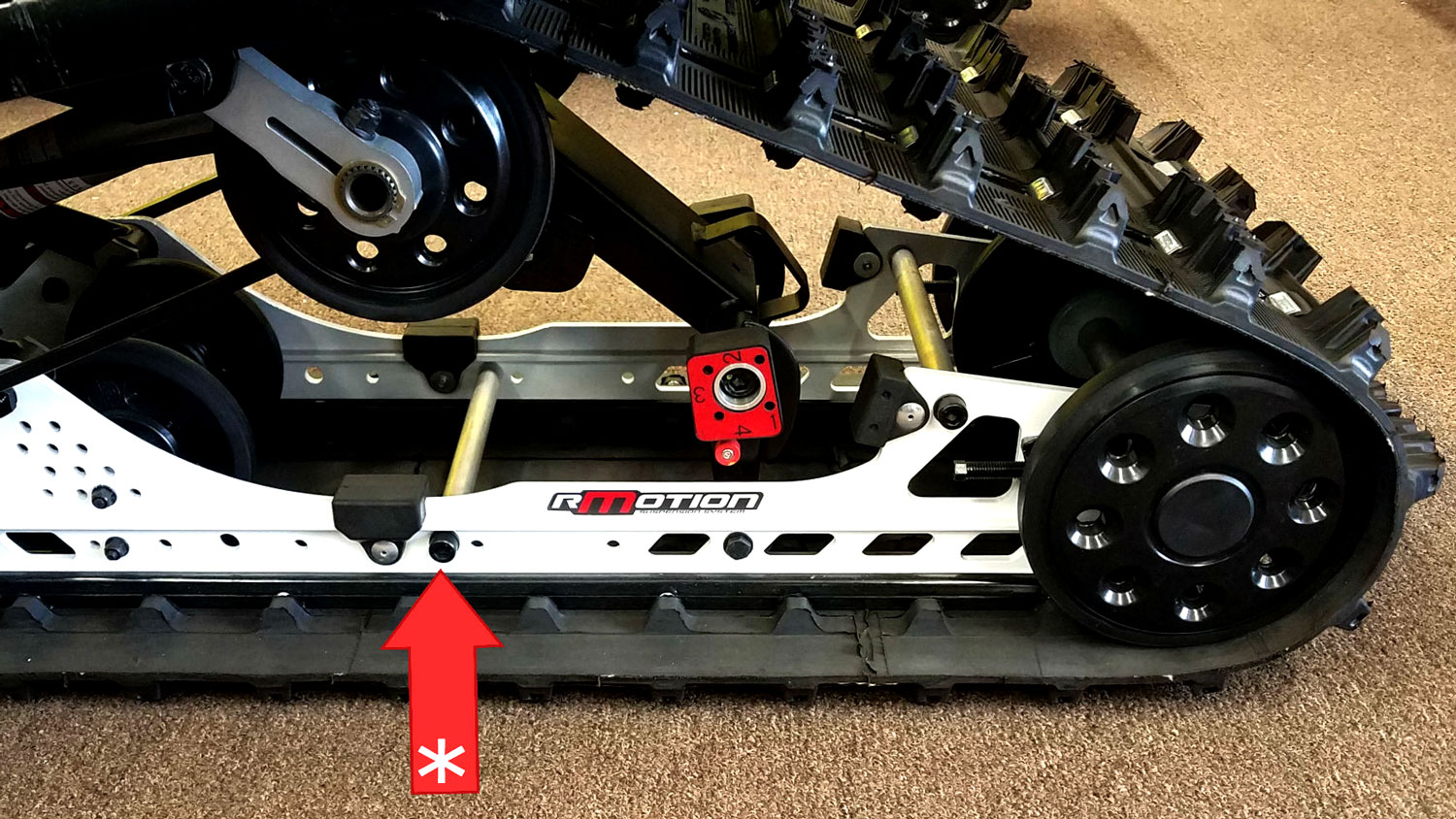

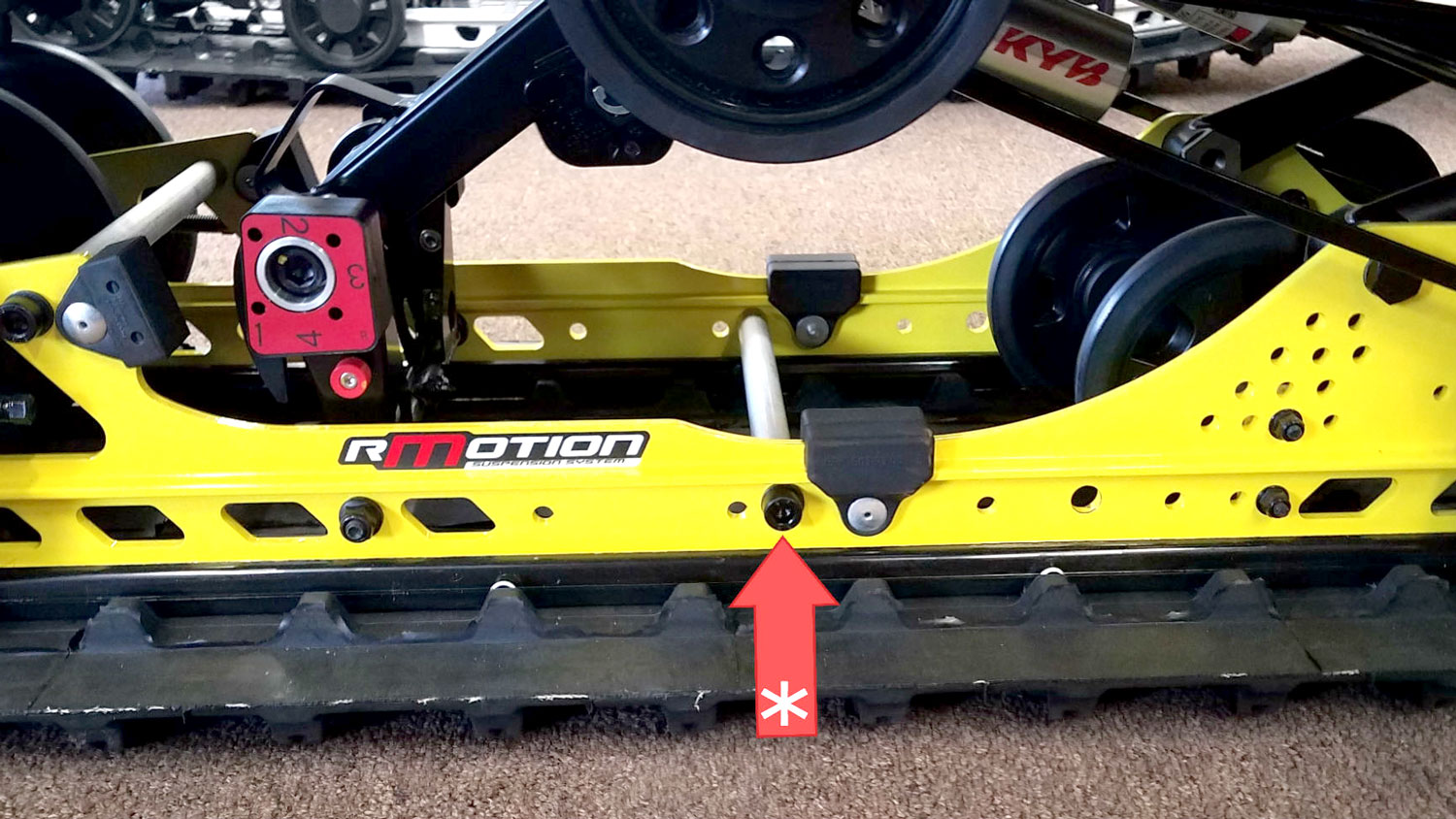

The following photos are from a

2016 SKIDOO XRS

This is what your snowmobile shocks look like if they have not had their shock oil changed….

(Staining from the acidic nature of the oil that was not changed in a proper time frame. This staining is permanent and affects the performance of the shock over its life. If you have hpg or KYB shocks, they are manufactured at the factory with what they call a “break-in” oil and it should be changed after 3 to 700 miles of use without fail. After that, longer shock service intervals are acceptable.)

SNOWMOBILE SHOCKS

SERVICES

Beyond snowmobile shocks,

Fink’s Performance Suspension

also services motorcycle shocks & SXS/UTV shocks

Providing you with the highest quality snowmobile shock service available in the industry.

As a full independent, we can use the oil, seals, and methods of our choice, therefore we are not locked into a manufacturer’s recommendation or products.

With over 21 years in the snowmobile shock industry, and 30 years combined experience with shocks in the racing performance industry, Brad has a unique understanding of what works and what doesn’t.

So when your skis hit the snow you can be riding, confident with Brad’s A/C Performance, builder of the BLT, the ride that set the standards by which all snowmobile suspensions are built today.

SNOWMOBILE SHOCKS

ABOUT US

Founder of Brad’s A/C Performance, Snowmobileshocks.com and Bradsautoglass.com

Brad Finkbeiner

Bradley Finkbeiner founded Brad’s A/C Performance in 1987 and later with the advent of the Internet, Brad established snowmobileshocks.com and snowmobiletracks.com in 1996.

Education includes the following schools:

- Dale McDowell Dirt Late-model school

- Afco/ Rocket Chassis racing school

- CJ Raeburn racing school

- Penske shock school

Founder of Fink’s Performance Suspension

Brian Finkbeiner

Snowmobileshocks.com and Brad’s A/C Performance is proud to announce the addition of new blood and ideas to the company.

Brian Finkbeiner, Brad’s son, is now on board with the company and brings the youth and different riding styles of many of today’s riders. Brian brings to the table the style of standup riding and big jump, risk-taking, and adventure riding.

So when you deal with Brad’s A/C Performance you get a wealth of understanding and knowledge and the best products and services in the business. And as always, the 100% satisfaction or your money-back guarantee. If you’re not completely satisfied with our products return them for a full refund.

SNOWMOBILE SHOCKS

PARTS

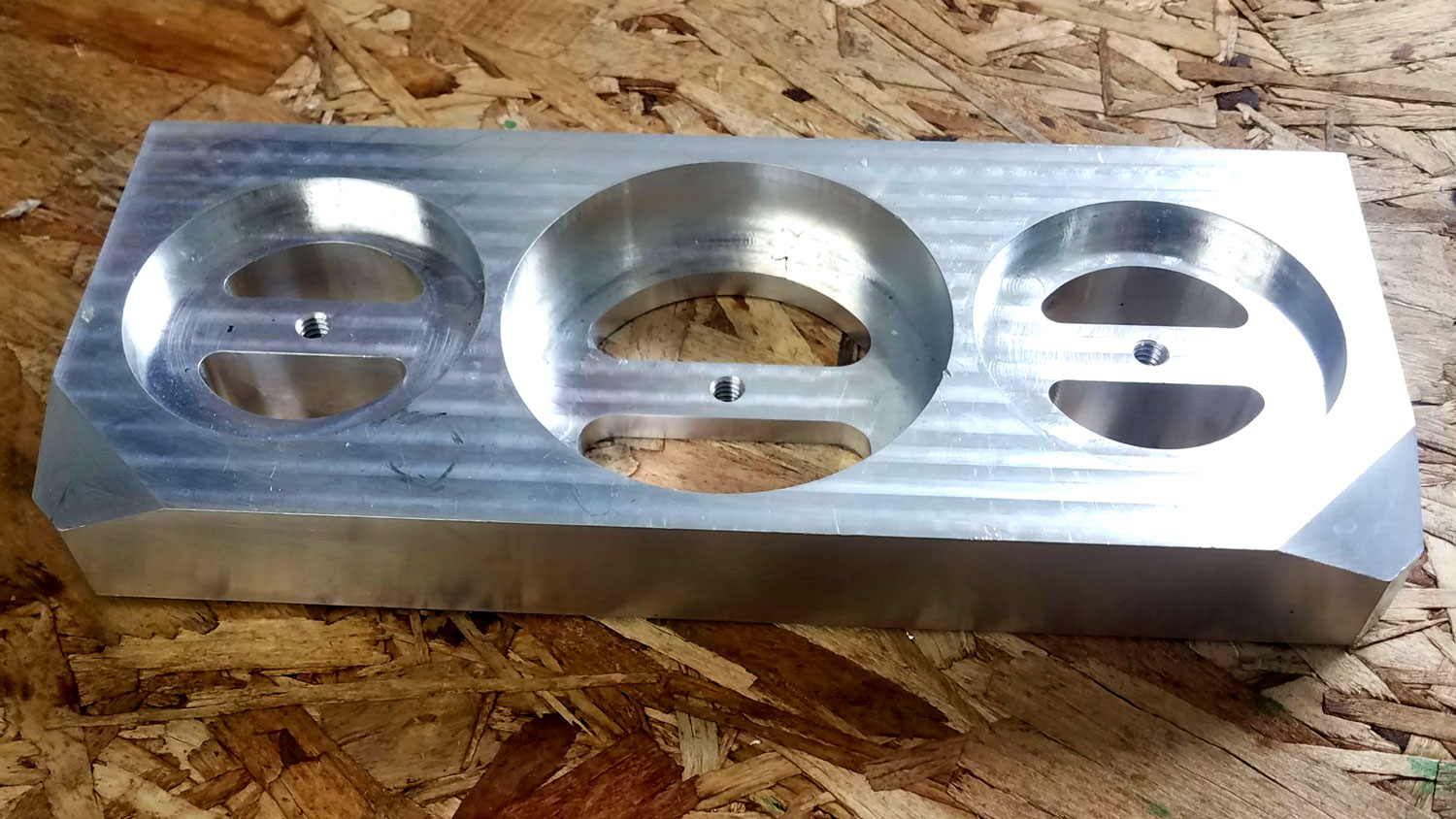

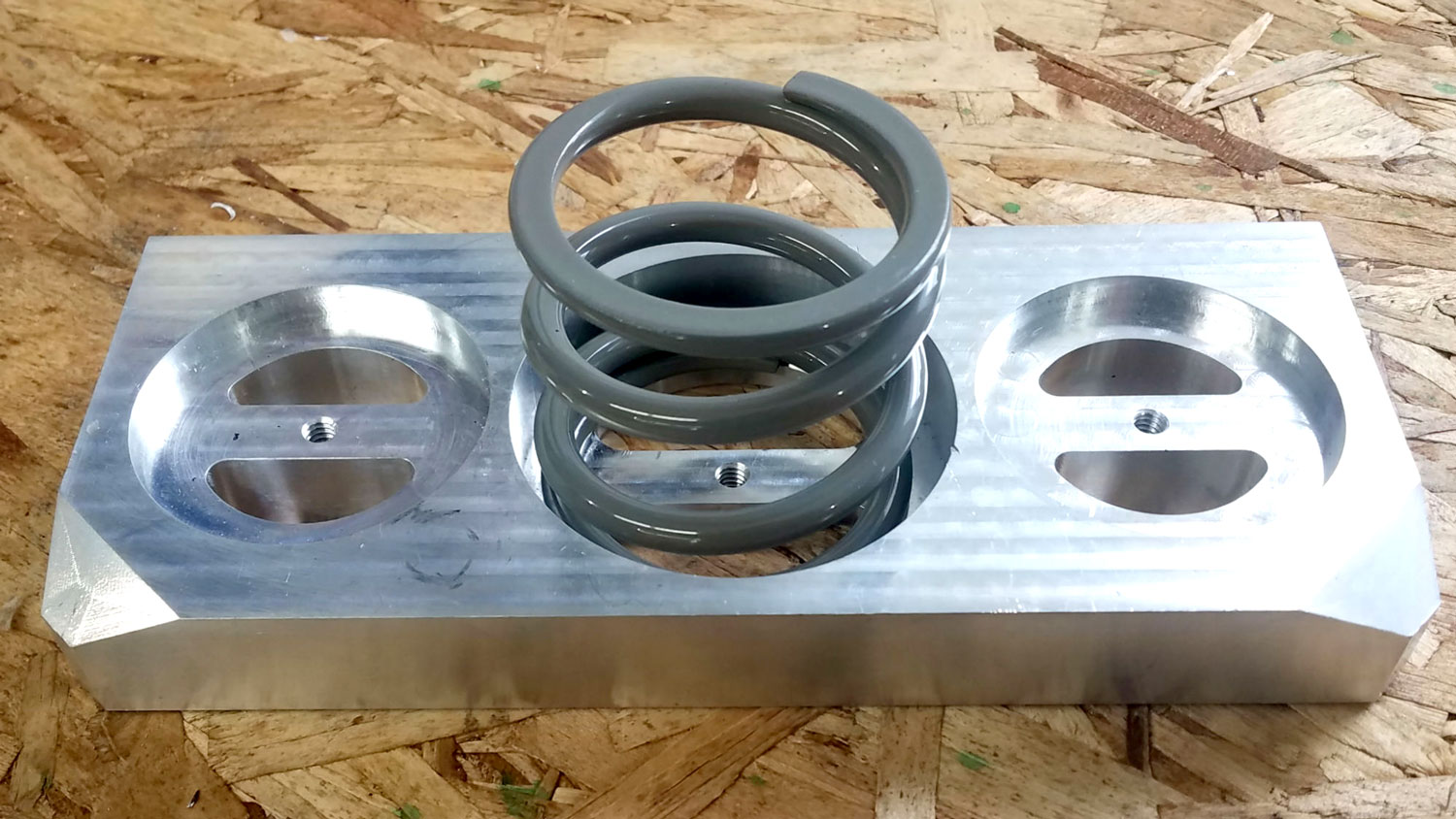

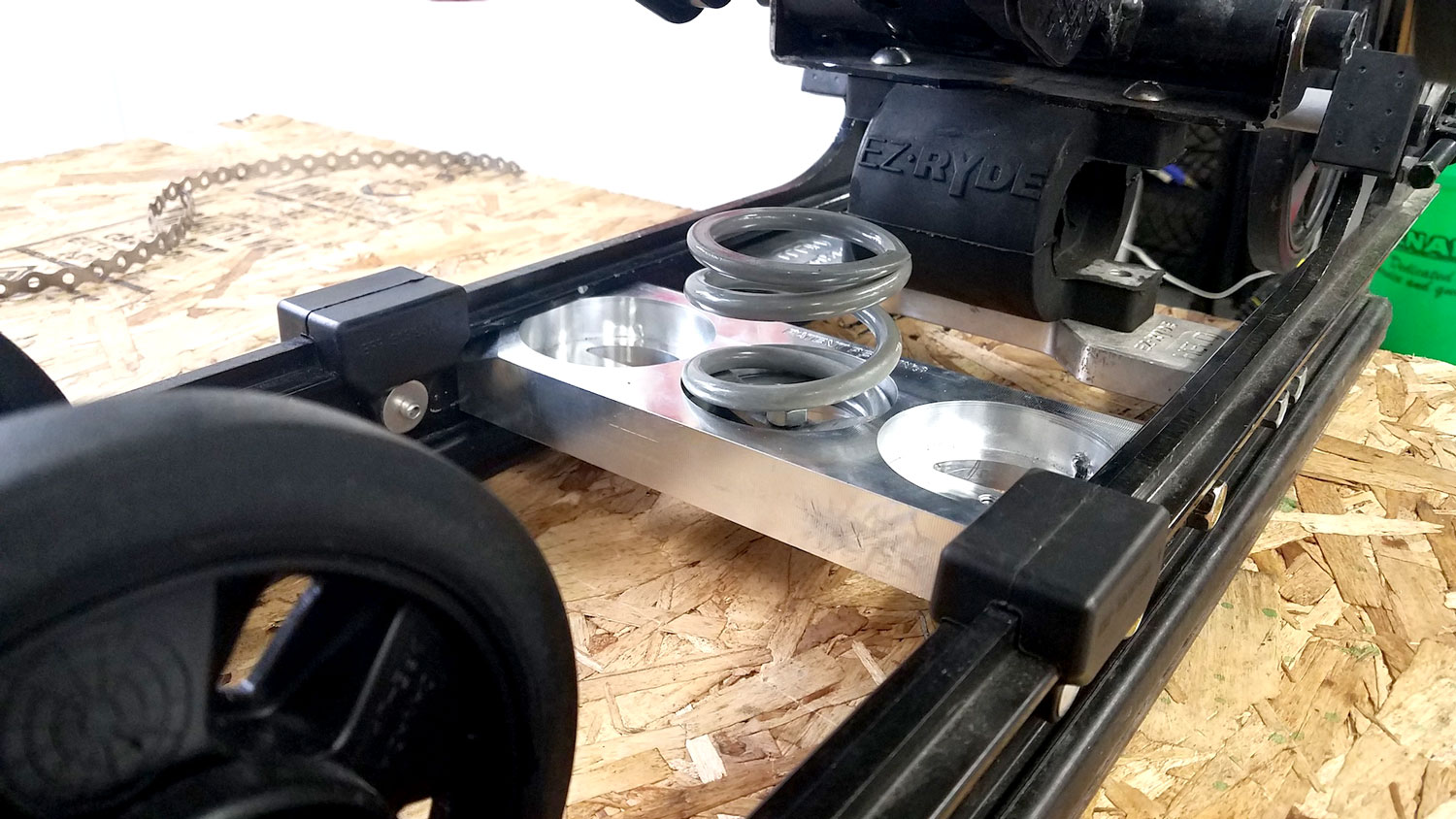

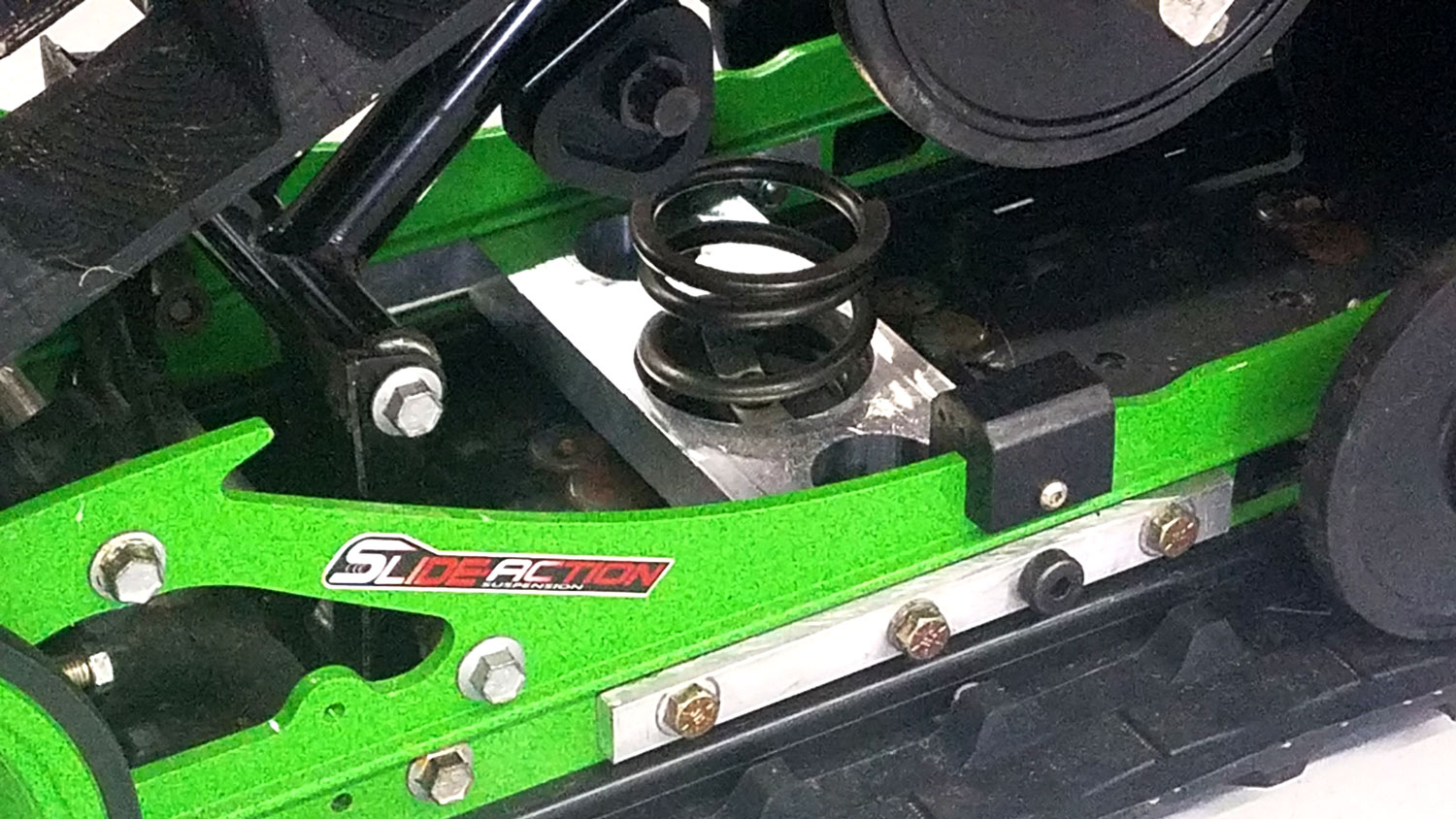

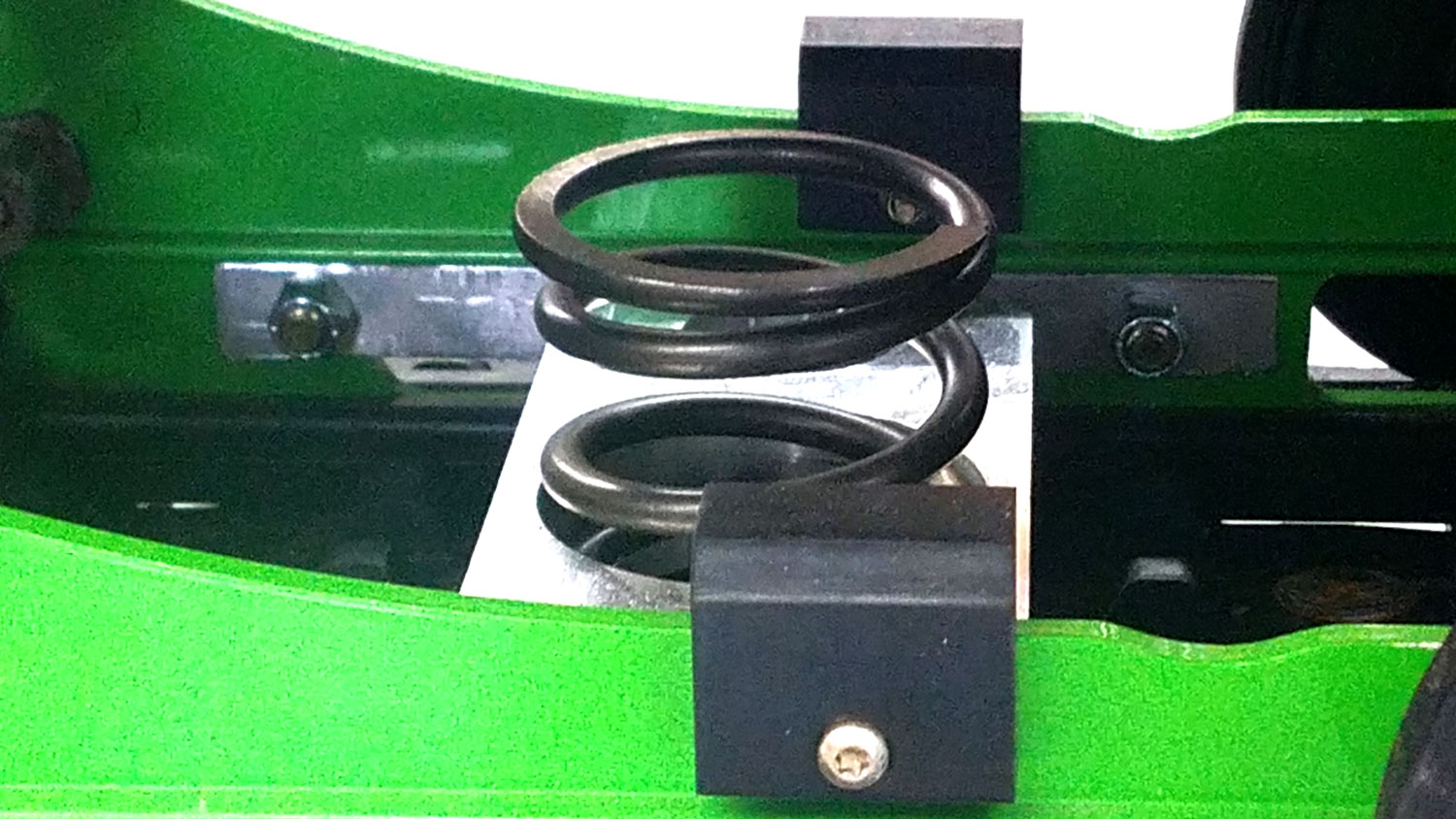

The Missing Link

Snowmobile Comfort Ride

Brad’s A/C Performance has done it again to revolutionize rear shock suspension tuning for a more comfortable snowmobile ride.

What this does is allows you to tune the rear suspension for a more comfortable ride yet still have resistance to bottoming in that big blowout bump.

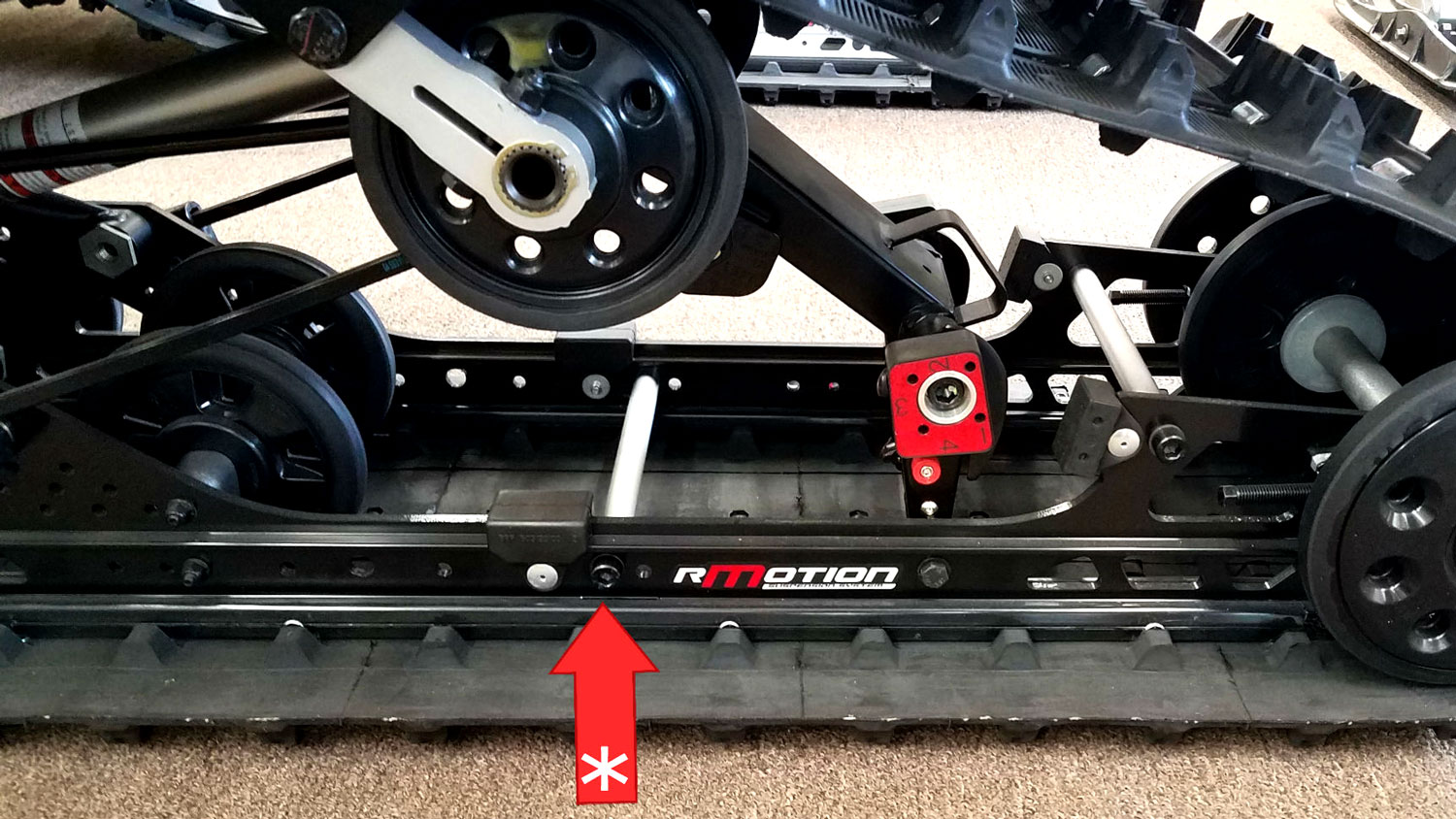

Power Steering | Electric Assist | Snowmobile Upgrade for ski-doo Gen 4 & Gen 5

Installing an electric power steering assist on your snowmobile offers several key benefits:

- Reduced Fatigue: Power steering significantly reduces the physical strain on your arms and shoulders, especially during long rides or in challenging terrain. This can enhance your overall riding experience and reduce discomfort.

- Improved Handling: Power steering provides smoother and more precise control over your snowmobile. This can be particularly helpful in tight corners or when navigating through obstacles, improving your ability to maneuver safely and effectively.

- Increased Comfort: Reduced strain on your upper body leads to greater comfort and less fatigue, allowing you to enjoy your rides for longer periods without experiencing pain or discomfort.

- Enhanced Safety: With better control and reduced strain, you can focus more on your surroundings and potential hazards, improving your overall safety on the trail.

- Increased Confidence: Power steering can boost your confidence in your ability to handle your snowmobile, especially in challenging conditions. This can make your rides more enjoyable and less stressful.

Overall, installing an electric power steering assist can significantly enhance your snowmobiling experience by providing improved comfort, control, and safety.

Brad’s A/C Performance

has hundreds of parts for Arctic Cat snowmobiles

Buy snowmobile parts on eBay

or contact us at technical support to make your purchase over the phone

Thanks, Bradley

SNOWMOBILE SHOCKS

CONTACT US

Monday through Friday 8:00am to 5:00pm (EST)

Saturdays, Sundays & Federal Holidays please leave a message.

We will contact you within 24 hours of the first business day.

Shipping Address:

10199 ROOP ROAD

KINGSLEY, MI 49649-9515